The supporting structures for gates and wickets are traditionally made of galvanized steel. Further processing depends on the tasks – the steel base can be simply painted or coated with powder pigment for more effective corrosion protection.

But even with high-quality galvanizing and high strength of the polymer, steel remains vulnerable to rust. Due to the nature of the installation and the stresses arising during operation, even the highest quality supporting structures made of steel can begin to rust over time.

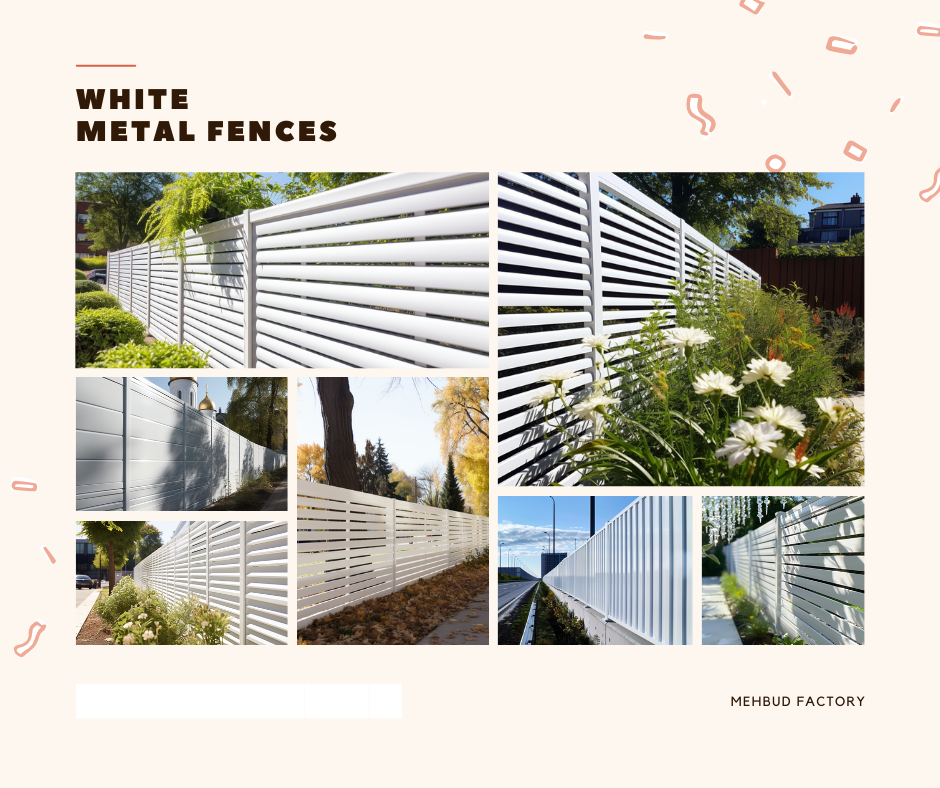

To eliminate the risk of corrosion, the Mehbud plant offers a new line of products – aluminum load-bearing structures.

Aluminum frames for gates and wickets: advantages

The decision to produce aluminum frames for gates and wickets was made on the basis of a study of the previously installed steel structures. For almost all such products, corrosion problems were relevant to one degree or another. In addition, the slightest flaws during installation led to deformation and subsidence of parts.

The advantages of aluminum products:

- High mechanical strength. With the correct selection of metal thickness, the structure is not inferior in strength to steel.

- Light weight. Aluminum is a light metal, so the weight of the frame is proportionally reduced.

- Configuration accuracy. Plastic aluminum blanks are easy to form, therefore, parts can be produced from this material with maximum precision.

Well, the main plus is maximum corrosion resistance. Aluminum, which is also treated with a protective compound, is not afraid of rust. Even in the most difficult climatic conditions, parts do not deteriorate over time, maintaining their strength and original appearance.

Price and service life

The only parameter by which aluminum structures are inferior to steel ones is their higher price.

But at the same time:

- The service life of the aluminum frame is significantly longer due to its greater corrosion resistance.

- The aluminum structure is much less likely to require repairs – even cosmetic ones.